Broetje-Automation introduces new product STAXX Box at JEC Paris

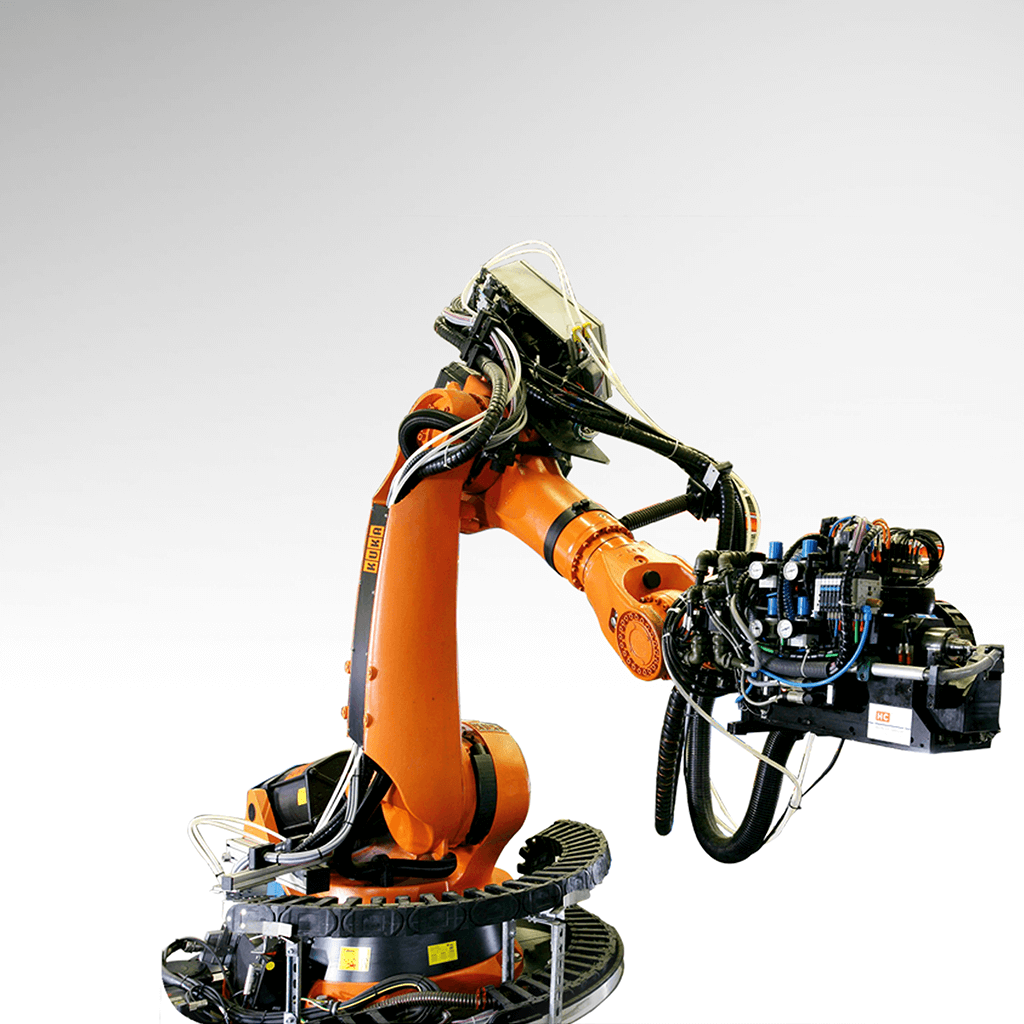

At the JEC World 2023, Broetje-Automation has launched a new box-sized fiber placement system. The STAXX Box extends the STAXX product family with a compact 4-axis fiber placement machine designed for cost-effective production of small parts.

The “plug and play” system integrates a standardized single tow end effector with a rotating layup table in the smallest installation space. With its multi-material capability and compact design, it can be easily relocated and is an ergonomic and user-friendly system ready for production.

Plug and Play option for AFP manufacturing

This years’ JEC Paris is the stage for a new product introduction by Broetje-Automation. The STAXX Box, completes the STAXX family of AFP systems. As a robust machine for multiple materials the STAXX Box offers the well-known advantages of the larger STAXX systems such as STAXX Compact and STAXX One in one compact and flexible system. Various material types such as PrePreg, TowPreg, DryFiber, ThinPly, Thermoplast, etc. can be processed in widths from ¼ to 2 inches.

Discover more videos on JEC Composites Web TV.

Options for controlled heating concepts using an infrared emitter, diode laser, or flash-lamp allow optimized processes and heating of the materials for resource efficient production. This ensures that the machine can handle a wide range of manufacturing processes. The STAXX Box combines flexibility with industrial readiness and, thanks to its modular concept, offers good accessibility for easy maintenance and an ergonomic working environment.

One of the special advantages of the STAXX family is the digital twin, simulation and offline programming software. Broetje-Automations larger Systems already come with a Digital Twin. Likewise, it is now also available in the STAXX Box. Additional features such as the CAM system for offline programming based on 3D/2D CAD data and internal water cooling make it a cost-efficient approach to automated production.

Lightweight and sustainable solution

The lightweight configuration of the STAXX BOX requires no foundation and uses standardized system components, further reducing overall production costs and providing a sustainable solution for customers through optimized production parameters while scalability is possible at any time.

“We are excited to open a new market segment with the STAXX BOX ,” says Raphael Reinhold, Head of R&T Composites at Broetje-Automation. “This machine offers a range of features that make it ideal for use in the manufacturing industry. It is also a great tool for businesses looking to automate their production processes of small composite parts.”

Broetje-Automation is showcasing this new product at JEC World 2023, hall 5, booth N82.