Nawa presents nano-based ultra-strong, multifunctional advanced composite technology at JEC World 2023

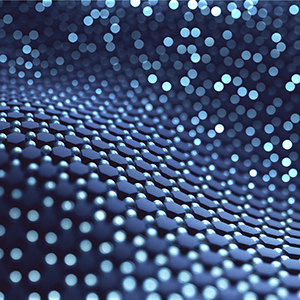

NAWA’s senior team, including its CEO Antoine Saucier, will be available throughout the show to discuss how its proprietary and revolutionary Vertically Aligned Carbon Nano Tubes (VACNT) technology enhances the performance of next-generation advanced composite products, with applications in the sporting goods, hydrogen storage, aerospace and automotive sectors.

NAWA’s innovation results in stronger, lighter and more advanced materials, with its NAWAStitch solution solving one of the biggest issues with common composites – interlaminar cracking or delamination.

Applied as a universal or localized interlaminar reinforcement of prepreg carbon fiber systems, NAWAStitch acts like a ‘nano-velcro’, preventing cracks from bridging across the interface, providing double digit positive deltas in mechanical enhancement, creating a virtually unbreakable material.

NAWAStitch creates a composite with a 900% increase in impact damage tolerance, while also offering a 20-30% reduction in weight. The revolutionary physical qualities of this breakthrough material offer many advantages to a number of industries and sectors.

Virtually unbreakable sporting goods

As a reinforcement solution to heighten impact tolerance and increase lifetime, it offers the sporting goods industry high-performance, near-unbreakable equipment. Consumers of sports goods that are typically subjected to extreme impacts such as golf club heads, hockey sticks or mountain bike wheels can benefit from enhanced performance, reliability and longevity thanks to NAWAStitch. In addition, NAWA’s cost-effective and efficient mass production of VACNT technology means there is a short time-to-market advantage, delivering greater play today.

Stronger, lighter hydrogen storage tanks

Safety is of paramount importance when storing hydrogen, which is kept in highly-pressurized tanks. NAWAStitch’s application can provide stronger, but crucially lighter tanks, contributing to weight savings on zero emission vehicles. Its performance qualities stop cracks from bridging across the interface of composites and achieve consistent behavior of cracks within a ply.

NAWA’s first POC testing of a liquid hydrogen tank with VACNTs in cryogenic conditions demonstrated 20-50% less microcracking compared with typical composites, a result that proves its great benefit and importance to this market.

Multifunctional composites for tomorrow’s airplanes

NAWAStitch’s versatility can also be applied within the aviation sector. Not only can VACNT be used to dramatically strengthen composites used in aerospace, but the nano-material can also carry and store electrical energy, with benefits in anti-icing and de-icing, structural health monitoring or even structural energy storage, giving a composite component multifunctional capabilities.

Temperature-controlled battery casings for next-gen automotive EVs

As well as bringing lighter and stronger hydrogen tanks, NAWAStitch has multiple applications in automotive. For example, the nano-material’s innovative combination of greater strength combined with the ability to carry electric current can be applied to next-generation composite electric vehicle battery casings, that are not only stronger and safer, but by applying a current to the nano-layer, offer the ability to keep the battery at a constant temperature, avoiding the requirement for additional thermal management, helping to prolong the performance and life of the cells inside.

Antoine Saucier, new NAWA Technologies CEO, commented: “We are very excited to present NAWA’s ground-breaking NAWAStitch technology at JEC World, our revolutionary nano-material can transform a wide spectrum of industries, providing greater performance, longevity and safety to composites used in everything from sporting goods to aviation and automotive. The potential of this technology is enormous – and consumers will soon be enjoying its advantages thanks to its quick-to-market mass production.”