Arkema will present a unique portfolio of materials at JEC World 2023

The composites market, a dual challenge of performance and sustainability! Arkema’s innovative and sustainable materials address some of the major challenges facing our society: Decarbonizing the industry, accelerating the development of new energies, promoting the circular economy and taking actions for health and well-being. Through their resins, additives, adhesives and 3D printing solutions, Arkema offers higher performance and more sustainable solutions to meet the demands of the composites market.

Elium® resins, now available with recycled content

In 2023, Arkema is launching new Elium® resins using recycled contents that increase sustainability of composites parts.

A first generation of Elium® containing at least 18% of recycled material is already available on the most popular grades and a formulation with 92% of recycled material is currently under test. The properties of these new Elium® resins remain the same as the previous grades with virgin components, from processability, manufacturing conditions to final composites and the same performance. The only difference is a lower environmental impact of the matrix used to manufacture composites and more sustainable parts than ever with Elium®.

Elium® is a unique solution for manufacturing composite parts using the same methods as those used for standard liquid resin parts, and include the major advantages of a resin designed for recycling.

Composites parts and manufacturing wastes containing Elium® resin can be easily recycled by depolymerization or mechanical recycling enabling upcycling and circularity of composites wastes.

Discover their solutions in a new sustainabilty corner on Arkema’s booth, the two recycling processes will be explained with the different steps.

Kepstan® PEKK, one K makes all the difference

This high-performance material provides a unique combination of properties over a very wide range of temperatures. This polymer family has exceptional advantages for processing and expands the application possibilities offered by the PAEK family. Kepstan® PEKK is widely used for the aerospace sector, in partnership with Hexcel.

UDX® Arkema composites are also semi-finished products!

During JEC World you will also discover UDX® PPA and UDX® PA11, unidirectional carbon fiber tapes impregnated with bio-sourced and recyclable thermoplastic resins.

UDX® PPA is a very high performance product particularly suited to the manufacture of high-pressure hydrogen gas storage tanks, thanks in particular to the properties of Rilsan® Matrix, which makes up the matrix of this composite.

Rilsan® Matrix is a polypthalamide with a unique combination of properties:

- high glass transition temperature (150°C), allowing it to resist the high self-heating of the tank during rapid filling,

- low melting point (260°C) allowing a reasonable process temperature for the implementation of the composite tape and thus an easy manufacturing of the tank.

UDX® PA11 offers a unique solution for the storage of liquid hydrogen at cryogenic temperatures due to the properties of its polyamide 11 matrix. The high elasticity and stiffness of polyamide 11 combined with the lightness and stiffness of carbon fibers make UDX® PA11 a product that is also highly appreciated in the field of sports and leisure. The completely bio-based and recyclable property of polyamide 11 and its production method based on sustainable and eco-responsible agriculture make UDX® PA11 an absolutely unique product that customers adopt.

Additives for tougher composites

Whether you need to improve toughness, strength, curing, adhesion or simply initiate the polymerization of your matrix, Arkema have a solution withing its portfolio.

- Reinforce the thoughness of your system:

The Clearstrength® XT MBS coreshell toughening agent enables a wide formulation versatility for the main types of matrixes on the market. The Sartomer® Advanced Resins masterbatch version of the coreshell offer a ready to use uniform predispersion. The Sartomer® liquid urethane (meth)acrylate oligomers can also be introduced in the matrix to fine tune the mechanical properties.

The Orgasol® ultra fine polyamide powders are particularly adapted to epoxy matrix, and highly efficient thanks to their spherical shape combined with a narrow particle size distribution.

The nanostructured acrylic block copolymers Nanostrength® act as additives at the very heart of the material. They help enhance the impact resistance of the matrix with no loss of module or temperature stability. They can be used both in epoxy or vinyl ester composite matrices and in structural adhesives.

Graphistrength® carbon nanotubes significantly improve the mechanical strength of composites. They also prevent the build-up of electric charges in the resulting components.

- Control the rheology of your composite:

Plastistrength® (meth)acrylic copolymers allow the viscosity control of (meth)acrylic and epoxy resins at low dosage.

- Lower VOCs of your matrix with specialty crosslinkers:

Sartomer® biobased monomers, with bio contents above 25%, are crosslinkers of choice for (meth)acrylic and epoxy matrixes. Those reactive diluents reduce VOCs, enhance mechanical properties and drive conversion while controlling the viscosity of the overall system.

- Initiate polymerization efficiently:

Luperox® and Retic® organic peroxides answer your curing challenges with grades tailored to room temperature or elevated temperature polymerization. They are fine-tuned for thermosetting resins. Sartomer® photoinitiators come in handy for hybrid systems involving a UV or LED curing step.

Smart Adhesives

Bostik will reveal its adhesive solutions for composite parts including its structural MMA (SAF&FIT range), its instant adhesives (Born2Bond™) and its sealants (SMP and extended range). During JEC World, you will also find the new Pliogrip™ range (2k-polyurethane and 2k-epoxy) with a focus the safer low monomer polyurethane adhesives Pliogrip™ 3540 (no mandatory training – REACH 74 regulation).

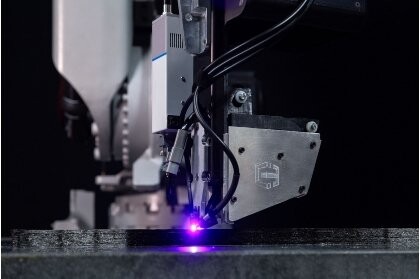

Today, Arkema offers a most comprehensive portfolio of high performance materials for additive manufacturing. They can provide solutions combining the best of both worlds: 3D printing and composites. The partnership between Continuous Composites and Arkema combines Continuous Composites’ patented continuous fiber 3D printing technology (CF3D®) with N3xtDimension®photocurable resin solutions. The partnership launched fully formulated materials last year PolyMat™ High Tg for printing of continuous carbon and glass fibers to produce lightweight, high temperature performance structures and CeraMat™ Carbon/Carbon resin for the creation of Carbon Bonded Carbon precursor parts for ultra-high temperature applications.

Designed for powder bed fusion, Arkema will be present with its Rilsan® fine powders Polyamide 11, high-performance materials, 100% bio-based materials and recyclable thanks to Arkema’s recycling Virtucycle® program.

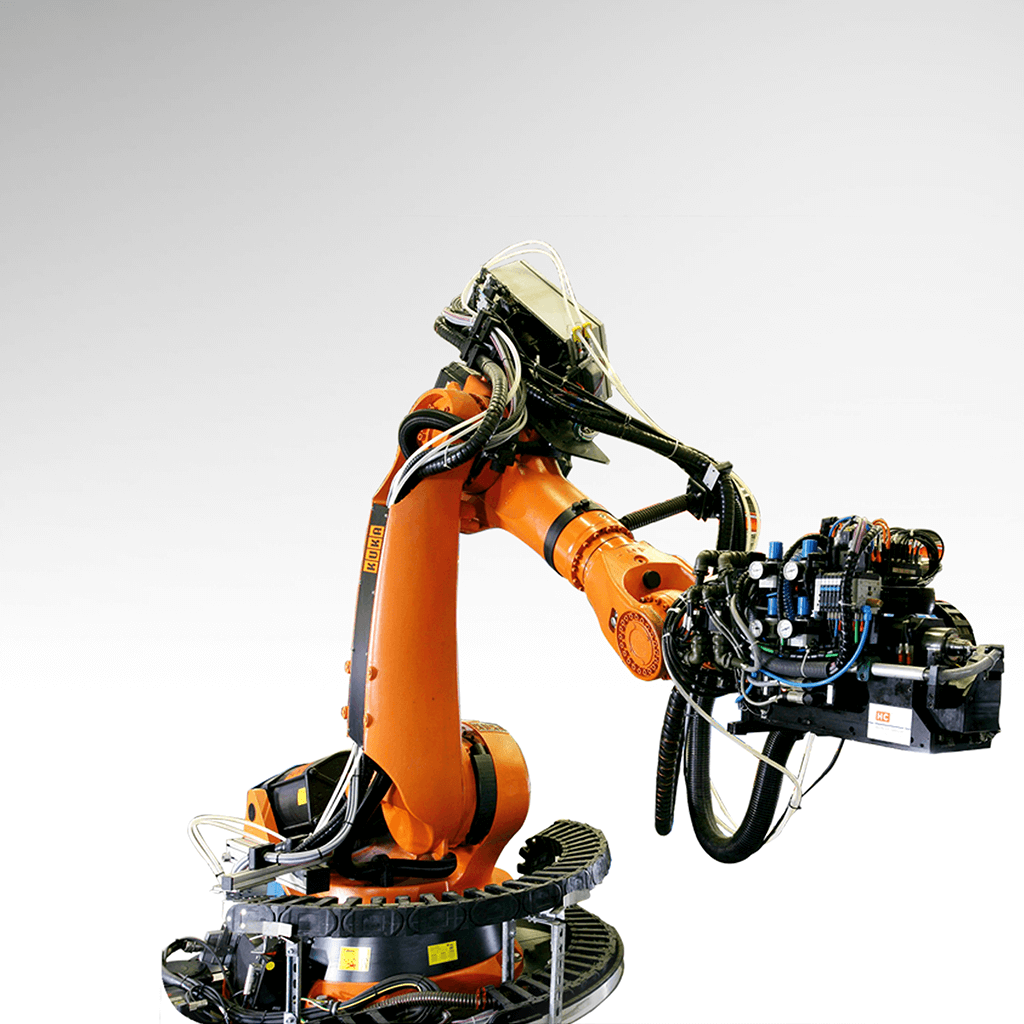

Arkema with its high performance polymer Kepstan® PEKK is partnered with 9T Labs (Zurich), a start-up specializing in the 3D printing of thermoplastic composites that has developed a technology that automates the manufacture of composites using additive manufacturing (AM) and advanced software algorithms.

Piezotech®, electroactive polymers for high-tech applications

Arkema is a leader in the production of a range of electroactive polymers: Piezotech®. These materials offer endless possibilities by enabling motion or thermal energy conversion into electricity and vice versa with the intrinsic advantages of polymers: processability, flexibility, lightness & low cost.

Those polymers have remarkable potential for monitoring the structural health of composites like hydrogen tanks, wind turbine blades etc.: high sensitivity to acoustic waves, deformation, and temperature. They are used in acoustic detection to identify cracks, impacts or in ultrasonic sensors to generate waves and then detect the differences in propagation, thus allowing a fine analysis of the structure.

Compared to standard piezoelectric ceramics, sensors based on Piezotech® can be mounted on curved surfaces because they are flexible. Also, due to their polymeric nature, they can be integrated into the core of composite like tanks and can be printed on large surfaces. The absence of toxic and non-recyclable heavy metals, their light weight and low energy consumption make them the materials of choice for the intelligent composites of tomorrow.

Meet Arkema at JEC World 2023, hall 5, booth V39.