Airbus Atlantic showcases two demonstrators for the aircraft of the future at JEC World 2023

For the first time, Airbus Atlantic will be present at JEC World 2023, the world’s leading annual industry event gathering the whole value chain of composites, from 25 to 27 April 2023 at Paris Nord – Villepinte Exhibition Centre.

Airbus Atlantic is an expert in design, production and integration of complex composite and hybrid aerostructures. At JEC World 2023, Airbus Atlantic will showcase two demonstrators for the aircraft of the future:

- A new generation of composite rear fuselage panels for the A220: manufactured in their Salaunes site, these new-generation panels made of high-performance carbon fibre and thermoset prepreg resin enable significant weight reduction, better resistance to corrosion and increase the interval between inspections.

- An innovative radome manufactured by an automated process: radomes are exclusively made of non-metallic materials, to meet dielectric and radiofrequency constraints. Developed in their Nantes site, this very first mock-up of a radome manufactured thanks to an automated composite fibre lay-up process, involves a change in design and significantly improves industrial performance.

About Airbus Atlantic:

In their composites facilities in Méaulte, Nantes and Salaunes (France), they manufacture a wide range of thermoset and thermoplastic aircraft fuselage parts and aerospace equipment, using cutting-edge composite technologies:

- Equipped aircraft sections and work-packages (nose fuselage section and centre wing box for the A350, aft fuselage panels for the A220, equipped wings for ATR)

- Large complex parts for all type of aircraft (radomes, air inlets, wing flaps, keel beams, seat shells…) as well as elementary parts (stringers, struts…)

- Cockpit furnishing (for A320, A400M)

- Cabin furnishing: window panels, bins, lavatories, ceiling, partitions… (ATR 42 / 72)

- Premium passenger seat shells (for all types of aircraft)

They use various technologies such as Automated Fibre Placement (AFP), Automated Tape Laying (ATL), Infusion / Resin Transfer Moulding (RTM), compression moulding, filament winding, hand lay-up, Out of Autoclave process (OoA), robotized fibre placement, dry fibre.

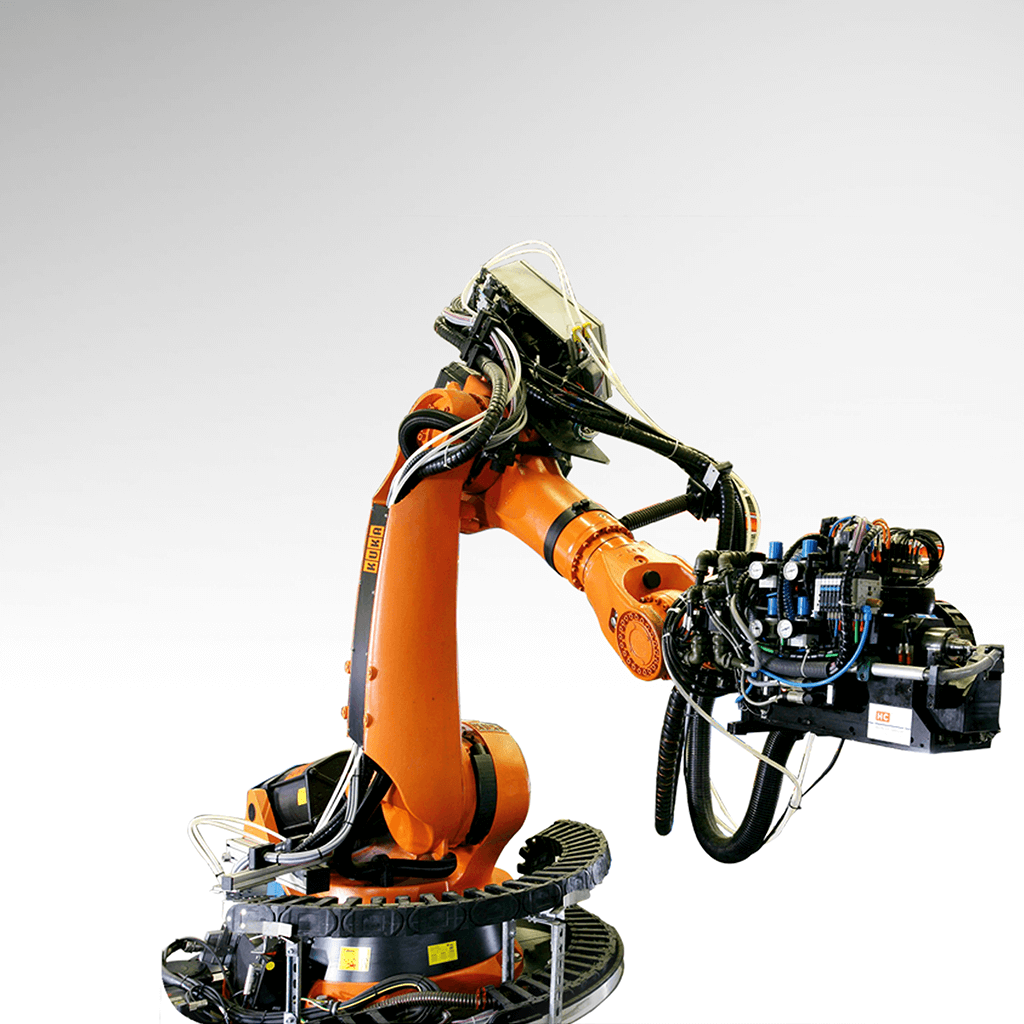

In their three research centres (Airbus Atlantic Technocentre in Nantes, Atlantic Lab in Méaulte and Stelia Composites Expertise Centre in Salaunes), their engineers develop large, one-part, fastener free, 3D primary structures, manufactured by infusion or by non-autoclave welding and thermoplastic technologies. They also investigate innovative assembly processes based on advanced robotic solutions.

Meet Airbus Atlantic at JEC World 2023, hall 6, booth G65.