New Continuous Compression Moulding generation from company RUCKS for efficient manufacture of organic sheets at JEC World 2023

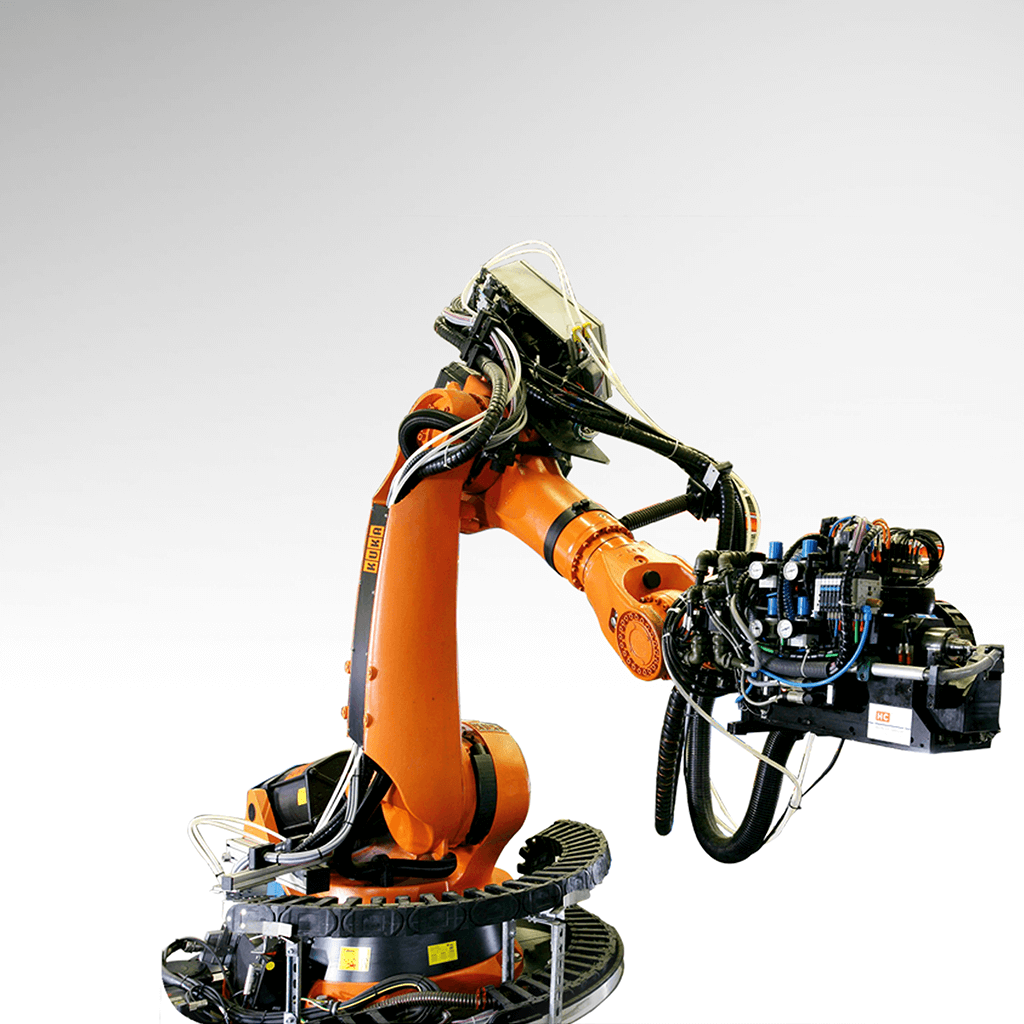

Economic lightweight construction is a major factor for the successful implementation of new automotive concepts in the 21st century. Fibre-reinforced plastics offer a particularly high potential for reducing the weight of vehicles. However, a major problem in this area remains the high manufacturing costs of the organic sheets. The new Continuous Compression Moulding (CCM) system from the company RUCKS offers a solution to this problem.

In addition to its considerably higher cost-effectiveness, the process has the great advantage that as well as the high pressing capacity that can be achieved, temperatures above 450° can also be reached effortlessly. This means that even PEEK can be processed using this procedure, which is extremely advantageous compared with double belt presses.

The system primarily consists of six stations. The unwinding station prepares the material that is to be consolidated on rolls. This means that six layers of material can be pressed into one organic sheet. If necessary, the number of laminate layers can also be increased.

A feed table ensures the individual layers are aligned correctly and the current material usage is always calculated on the control side using incremental length measurement.

Before the actual consolidation, the material is heated in a pre-press to approximately 100°C and pre-compressed with a press capacity of 3 kN. This makes it possible to also process awkwardly shaped non-woven fabric in the machine.

The material is pulled semi-continuously through the press together with the separating sheets by the feeder arranged behind the press. This achieves theoretical speeds of 200mm/s. Depending on the number and thickness of the layers, up to 1.7m of laminate can be produced per minute.

The core of the machine is the heating-cooling press with a press capacity of 2,000 kN, which is fitted with a synchronized hydraulic system. This is constructed with four press cylinders with power and location control. In addition to the very high plane-parallelism of +/- 0.02mm, a special feature of the design is the option of deliberately placing the heating plates in a sloping position (1.5mm/1.2m). Furthermore, the heating plates can be adjusted to six individual positions over a length of 1,200mm and thermally separated temperature zones (up to 451°C) have been installed. As a result, material-specific heating and cooling curves can be run without any problems to form the melt front in the direction of manufacture. A thickness measuring device is used for quality control purposes, which determines the precise thickness of the pressed semi-finished product at four measuring points using a laser sensor.

The final station of the machine is the cutting station, which cuts the endless material into defined pieces. Alternatively, the material can also be run with winders on a roll. All the stations are connected to each other on the control side and provide a fully automated process.

The machine, which is located at the Textile Research Institute in Chemnitz, Saxony, can process glass fibres, carbon fibres, aramid fibres, natural fibres, as well as PP, PA, PES, PPS, PEEK, PEI… or also hybrid non-woven fabrics (reinforcement fibres + thermoplastic fibres). Please contact STFI or RUCKS if you are interested in press trials.

In addition to the CCM system described above, RUCKS has supplied many CCM system over the last years. The newest CCM system is assembled in Japan right now. It has a production width of 1.3m. Concepts for systems with production width of 1.5m are ready to be build.

Meet RUCKS Maschinenbau GmbH at JEC World 2023, hall 5 – D79.