DLR Fused Bonding demonstrator will be exhibited at JEC World 2023

The production of complex lightweight structures made of fibre-reinforced plastic is virtually inconceivable without bonding. Creating a strong and durable bond poses a fundamental challenge in conventional bonding processes.

The fused bonding process developed at the German Aerospace Centre uses reactive joining surfaces to produce reliable bonds, the result being bonded components as if produced from a single mould. In addition to maximum bonding quality, the fused bonding process promises considerable savings on production costs as well as reduced development times and easier approval of bonded structures made of fibre-reinforced plastic.

Simple and highly effective

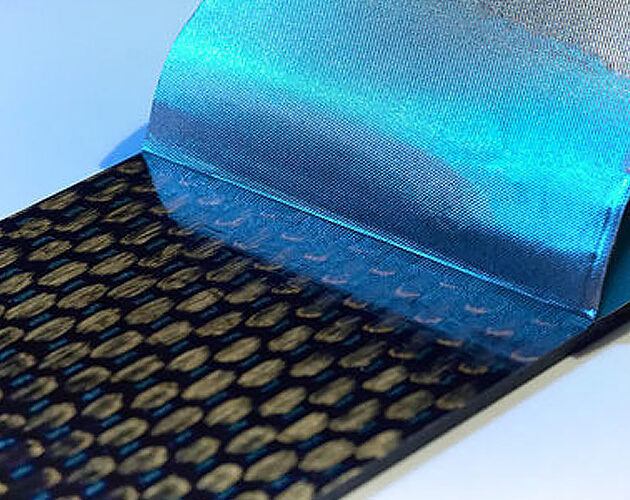

At the core of the new joining process is a special activation foil, which is applied to the preform as an outermost layer during the production of fibre-reinforced plastic. which is applied to the preform as an outermost layer during the production of fibre-reinforced plastic. Pre-treatment in the form of peeling off the foil does not occur until just before the execution of the joining process itself. In contrast to other methods, it is thus particularly easy to obtain a clean and reactive surface. In the event of contact with a liquid adhesive or matrix resin, a chemical cross-linking reaction occurs at the interface, during which a continuous polymer chain forms between component and adhesive. The result is a strong and durable bond with the properties of the polymer base material.

A solution for multiple use cases

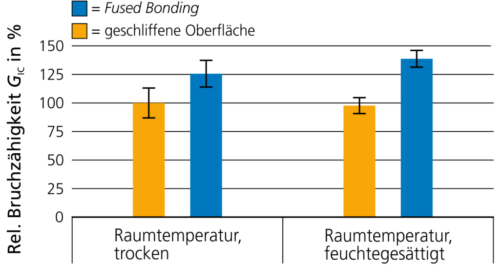

The process is suitable for a range of materials, including matrix resins and epoxy adhesives with low to high curing temperatures. Mechanical trials have shown that bonds created using fused bonding exhibit outstanding strength. When loaded to fracture, no failure occurs at the interfaces between the pre-treated fibre composite and the adhesive. From affixing the smallest of sensors to joining large civil aircraft structures: The fused bonding process can be used for a wide range of applications. It offers a number of technical, economic and ecological advantages over the state of the art.

Discover the DLR Fused Bonding Demonstrator at JEC World 2023, Hall 6, Stand S28.

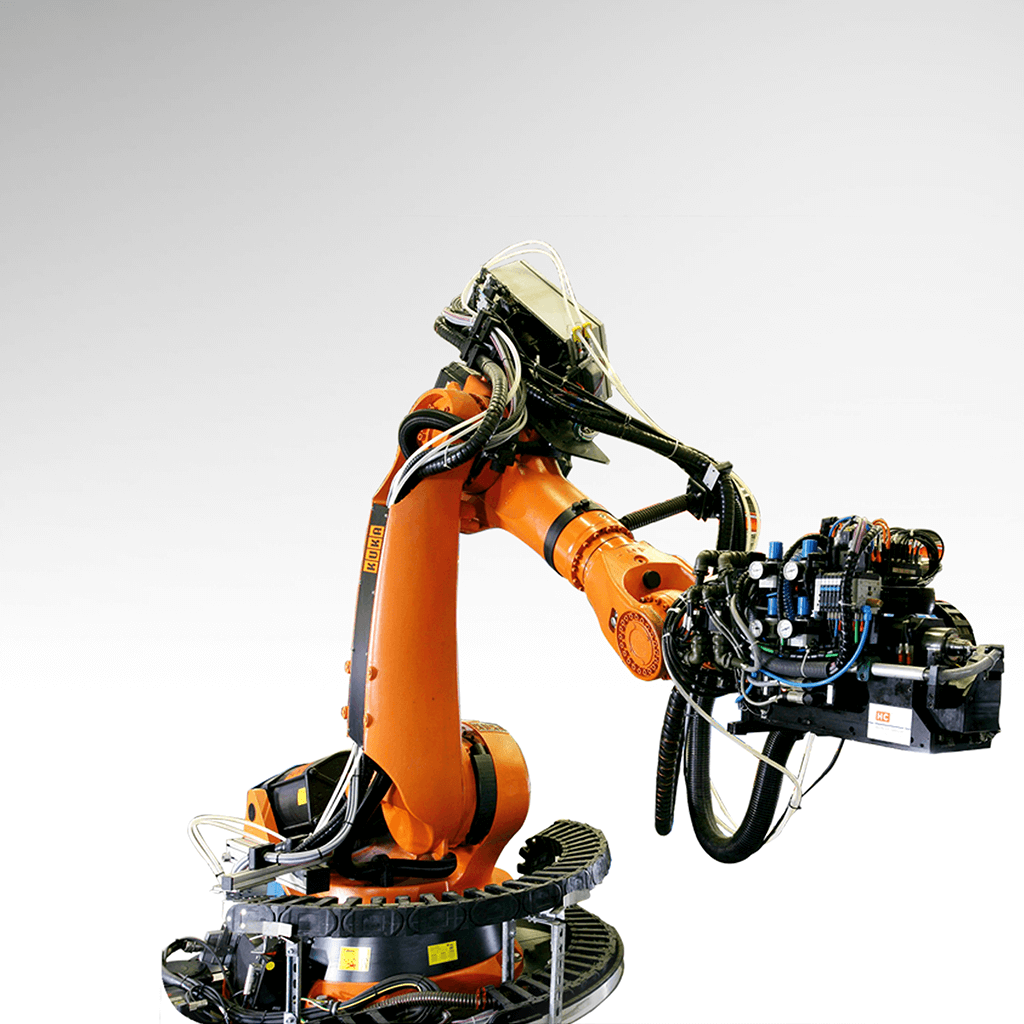

In addition, the EmpowerAX demo part on the topic “Additive Functionalization: Demonstration of an industrial process chain for local reinforcement”, will be also exhibited during JEC World 2023.

More information are available in this article published on JEC Website: Additive functionalisation & local stiffening using fibre-reinforced 3D printing in the EmpowerAX demo part exhibited at JEC World 2023