François Raguin, Technical Director of Pinette PEI

Pinette PEI has been operating for 160 years in the production of manufacturing lines comprising hydraulic presses or large assembly devices. JEC Composites Magazine interviewed Mr. Francois Raguin, Technical Director of Pinette PEI.

JEC Composites Magazine: Before addressing more specific topics, could you briefly describe your company’s activities?

François Raguin: Pinette PEI will celebrate our 160th anniversary at the end of September 2023. The production of hydraulic presses is our historical core business, with presses ranging from a few tons up to more than 10,000 tons of compression force.

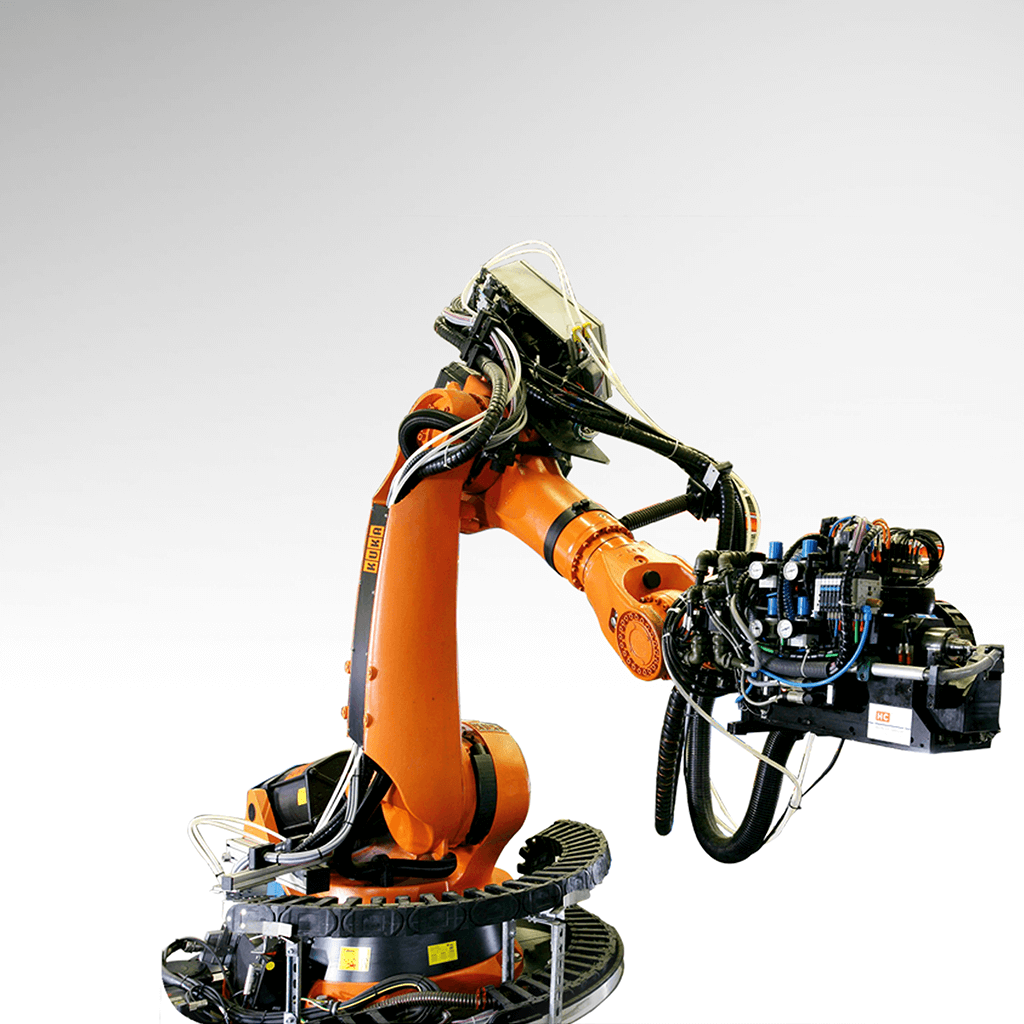

Over the years, we have gone from press manufacturers to designers of complete automated production lines, integrating robotic loading and unloading systems, heating and cooling units for tool temperature monitoring with a high level of precision, raw material preparation and part finishing (cutting, deburring, drilling, and ultrasonic cutting), as well as vision systems and assembly systems for steel or plastic parts.

Our lines are delivered 70% abroad and 30% in France, for applications in the aeronautics, space, defence, automotive, medical, energy and industrial equipment sectors.

Discover more videos on JEC Composites Web TV.

We can classify our products as: thermoplastic or thermoset composite processes, laboratory presses, test benches for oil drilling tubes, high-pressure presses for steel forming, and large assembly machines for heavy industries such as boatbuilding, nuclear and space.

We provide press retrofit services as well, and we want to develop this activity.

Our factory and development centres are based at Chalon sur Saône, France, and we have commercial and technical offices in the USA, Germany, and China.

JEC Composites Magazine: How did 2022 close for the machine tool sector? What are the prospects for 2023/2025?

François Raguin: After a slowdown in the past two years due to the COVID pandemic, the activity was good in 2022 and will continue to grow in 2023/2025.

Our development is supported by the defence and aeronautical industries, as well as new demands related to “smart cities”.

Export is a very important part of our activity, particularly to the USA, China and Australia.

Our customers choose Pinette PEI for our expertise in the definition of efficient and reliable equipment, but also for our ability to advise and co-develop processes taking into consideration the raw material behaviour and product requirements.

JEC Composites Magazine: TIFAANI, your amazing development platform, will be ready by 2023. Can you describe it?

François Raguin: TIFAANI is a versatile production line installed in Chalon-sur-Saône, Burgundy, France, that can carry out all the processes we are offering to the composite industry, namely:

- Consolidation of thermoplastic composite sheets

- Thermoplastic hot forming (up to 425°C)

- Carbon fabric preforming

- Resin Transfer Moulding

- Sheet Moulding Compound

- Bulletproof vest compression

The line will be equipped with a 1300-ton press with a loading and unloading robot, two infrared ovens, two thermal oil regulators, a high-speed, high-precision cooling unit, and a vacuum unit for SMC and RTM processes. It will be ready at the end of September 2023, for our 160th anniversary.

JEC Composites Magazine: Can you tell us which materials TIFAANI will be able to process?

François Raguin: The materials that can be processed on TIFAANI are thermosets and thermoplastics for SMC, RTM and stamping processes. In fact, the platform can handle the main raw materials used in the composite industry, whatever the part destination (aerospace, defence, automotive, etc.).

For example, these can be polyester or epoxy resin-based thermosets, or PP, PPS, PEEK or PE-based thermoplastics, with reinforcements based on carbon, glass and other types of fibres.

JEC Composites Magazine: What are the main advantages of choosing TIFAANI?

François Raguin: TIFAANI is a versatile tool dedicated to research projects, product development or the production of small numbers of parts.

The press was designed to maintain the same level of performance and precision whatever the level of effort, from 50 to 1300 tons, with speeds adapted to each type of process.

It is also equipped with an IO-Link network that makes it possible to connect in a very flexible way additional sensors, in addition to standard machine sensors, in order to improve processes, monitor product parameters, reduce energy consumption and improve maintenance.

The sensors will be connected to several software interfaces: Wonderware Intouch for process monitoring and IFM Moneo for maintenance and energy efficiency.

On top of that, we are working on an expert software interface to help technicians find the right recipe parameters depending on the characteristics of the raw material used.

JEC Composites Magazine: Innovation and know-how are two essential requirements to overcome challenges on the global market. What role does R&D play for Pinette PEI?

François Raguin: R&D is fundamental. Indeed, the knowledge of material processing and optimum parameters is important to be able to design the most suitable and efficient production lines for our customers.

Our customers are not just looking for a machine manufacturer meeting precise technical specifications, but also for a partner capable of helping them define and develop the best process and produce best-in-class parts. This is the reason why it is essential have the best level of knowledge in terms of raw materials, products, processes and therefore R&D programmes, and TIFFANI will help us and our customers.

JEC Composites Magazine: What application sectors and countries are you most focusing on?

François Raguin: Our first target application sector is aeronautics in Europe, because the required level of part performance and reliability is very high.

One project is co-financed by the French government’s France Relance and supported by the Bourgogne Franche-Comté region and Grand Chalon. It aims to develop the new generation of aircraft: more sustainable, lighter, and more energy efficient.

In terms of process, our first focus is thermoplastic hot forming. But all composite processes will be addressed because the technical solution depends on the parts and markets concerned.

JEC Composites Magazine: Finally, let’s take a look at the future: what are Pinette’s development strategies?

François Raguin: Pinette PEI’s strategy is to continue our growth in Europe and internationally thanks to our capacity for innovation and our expertise in materials, products, and processes. In our core businesses: aero, defence, heavy industries, automotive, but also in new markets related to sustainable development, such as “smart cities”.

If you would like to know more, Pinette PEI will exhibit at JEC World 2023, in Hall 6, Booth D83.