ZEBRA project achieves key milestone with production of the first prototype of its recyclable wind turbine blade

Wind energy, both onshore and offshore, plays a critical role in the world’s transition to carbon-free energy sources. With a product lifespan of 30 years and a wind turbine recyclability rate of 85% to 90%, the wind power industry is now looking to close the remaining gap by designing and manufacturing the first 100% recyclable wind turbine blade.

The ZEBRA (Zero wastE Blade ReseArch) project, driven by French research center IRT Jules Verne, brings together industrial companies and technical centers to demonstrate on a full scale the technical, economic and environmental relevance of thermoplastic wind turbine blades, with an eco-design approach to facilitate recycling. The project had been launched in September 2020, for a period of 42 months with a budget of €18.5 million ($21.8 million).

Towards highly recyclable composites

To accelerate the wind power industry’s transition to a circular economy for wind turbine blades, the ZEBRA project established a strategic consortium that represents the full value chain: from development of materials, to blade manufacturing, to wind turbine operation and decommissioning, and finally recycling of the decommissioned blade material.

- Arkema with Elium®, a thermoplastic resin, well known for its recyclable properties by depolymerization or dissolution. This resin has been used in the ZEBRA project.

- The project also benefits from CANOE expertise on polymer formulation, carbon fiber development and polymer recycling. CANOE developed a very innovative recycling process of fiber-reinforced acrylic composite material by dissolution method providing a high added-value recovery of both separate recycled methyl methacrylate monomer and recycled fiber.

- ENGIE is a world-class wind farm operator, with 8.5 GW under management, and the French leader of the wind industry, with more than 2.6 GW of installed capacities. Its purpose is to act to accelerate the transition towards a carbon-neutral economy, in particular through the sustainable development of renewable technologies.

- LM Wind Power is a world leading designer and manufacturer of wind turbine blades, with more than 228,000 blades produced since 1978. The Cherbourg factory associated with the ZEBRA project had produced the largest blade ever manufactured at 107 meters in length.

- Owens Corning is one of the world leaders in the field of glass fiber and composite elements and the inventor of patented High Modulus Glass technology that created step change performances in the wind industry the last decade.

- SUEZ, which helps cities and industries to intelligently and sustainably manage their resources, has brought its expertise in the eco-design of the materials used and in the best recycling techniques

Today the ZEBRA project is marking a new step forward on the industry’s transition to a circular economy with the production of the first prototype of its 100% recyclable wind turbine blade.

A strategic consortium that represents the full value chain

The 62m blade was made using Arkema’s Elium® resin, which is a thermoplastic resin well known for its recyclable properties together with the new high performance Glass Fabrics from Owens Corning.

LM Wind Power ont its side has designed and built the thermoplastic blade at its Ponferrada plant in Spain. This milestone is achieved after a year of material development and testing backed by sub-component level process trials by the consortium partners.

The liquid thermoplastic resin is perfectly adapted for the manufacturing of large parts by resin infusion, combined with Owens Corning high performance fabrics. The resulting composite material is delivering similar performances to thermoset resins but with a key unique benefit: recyclability.

Elium® based composite components can be recycled using an advanced method called chemical recycling that enables to fully depolymerize the resin, separate the fiber from the resin and recover a new virgin resin & High Modulus Glass ready to be reused, closing the loop. This method, developed by Arkema and CANOE partners, are tested on all composite parts including waste generated from production. Owens Corning is also in charge of finding solutions for fiberglass recycling through remelting or reusing in various applications.

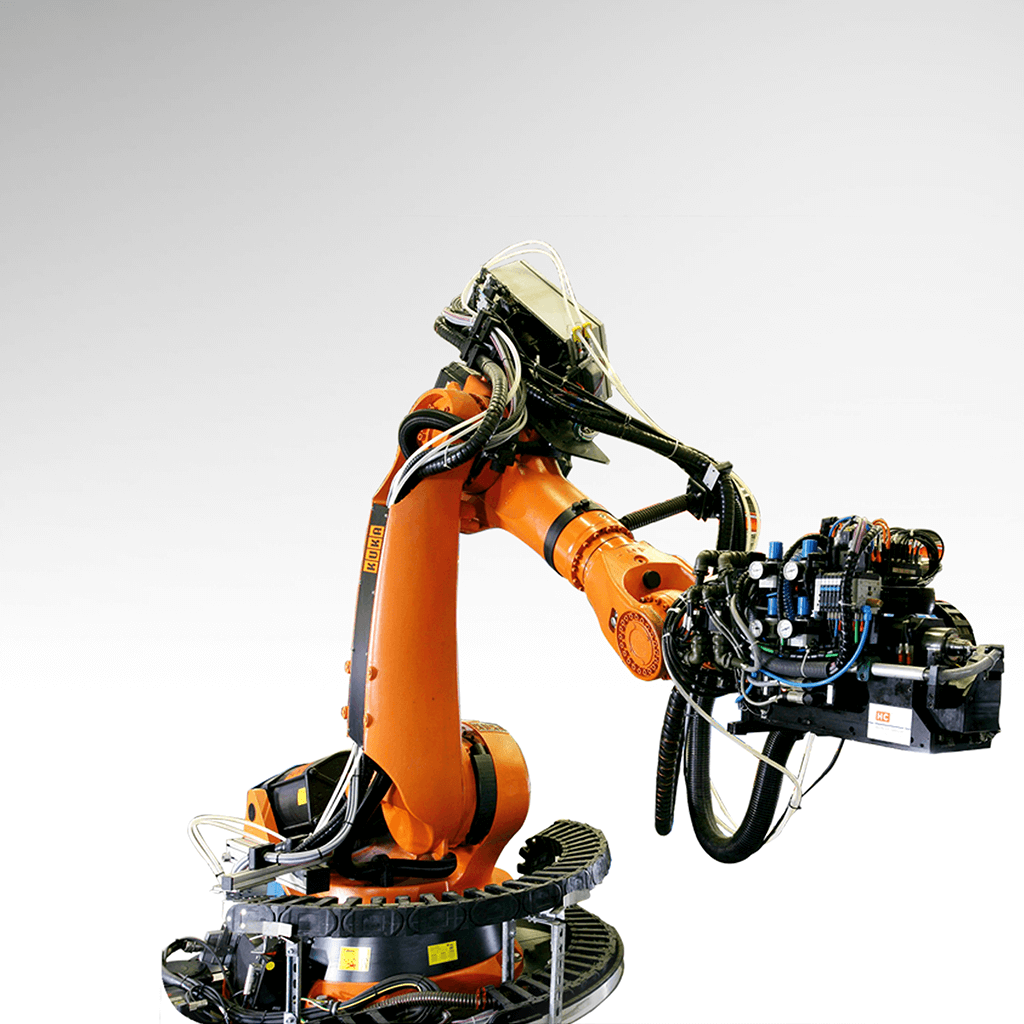

In addition to material testing and process trials, the companies have also made progress on developing and optimizing the manufacturing process by using automation, to reduce energy consumption and waste from production.

LM Wind Power will now start full-scale structural lifetime testing at its Test and Validation Centre in Denmark, to verify the performance of the composite material used in making the blade and its feasibility for future sustainable blade production. Once these tests are finished, the End Of Life recycling methods will also be validated.

The next steps are the recycling of production waste, the dismantling and recycling of this first blade and the analysis of the test results. By the end of the project in 2023, the consortium will have met the challenge of bringing the wind energy sector into the circular economy loop in a sustainable manner, according to the principles of eco-design.

A project supported by the entire wind energy sector

Céline Largeau, ZEBRA project Manager, IRT Jules Verne, stated: “Demonstrating a circular approach to wind turbine blades throughout their lifetime requires mobilizing a strategic consortium covering the whole value chain to guarantee valuable and precise industrial data and achievements. The ZEBRA project is a great opportunity to join together Arkema, CANOE, ENGIE, LM Wind Power, Owens Corning and Suez who are key leaders in the wind energy sector.”

Inventing 100% recyclable wind turbines is the challenge of Céline Largeau, Project Manager at IRT Jules Verne, and her team. A technological challenge that could have a major environmental impact.

John Korsgaard, Senior Director, Engineering Excellence, LM Wind Power states: “With this project we are addressing two crucial industry challenges. On one hand, we are progressing on our Zero Waste Blades vision by preventing and recycling manufacturing waste. On the other, we are taking blade recyclability to a new level: the end-of-life thermoplastic composite blade material has high value in itself and can be readily utilized in other industries as material compounds but can also be depolymerized and the resin reused in the production of new blades,”

Marcio A. Sandri, President, Composites at Owens Corning states: “Sustainability is a primary driver of innovation at Owens Corning, whether in our own work or in partnership with others. That’s why we are proud to be part of the ZEBRA consortium that reaches across the wind industry value chain to promote circularity in the production of wind energy. Keeping materials in the economy through circularity is a key strategy for decarbonization—designing products for circularity is critical innovation for reducing embodied carbon, necessary to meet the goal of limiting global warming to no more than 1.5° Celsius. Working with groups like the ZEBRA project is all about keeping with our mission to build a sustainable future through material innovation”

Rosaline Corinthien, CEO ENGIE France Renewables added: “A world first with ZEBRA: the manufacture of the world’s first eco-designed blade, the result of unprecedented industrial cooperation, led in particular by Engie, for 100% recyclable and zero waste wind turbine blades . With ZEBRA, wind power is accelerating its integration into the circular economy.”

Guillaume Clédat, Global sales and development director for Elium® resin, Arkema, commented: “Recycling end-of-life wind turbines is a major industrial and environmental challenge for the wind power industry, due to the considerable volumes involved. Being at the heart of the ZEBRA project, thanks to our expertise and our wide range of polymers for composites, we are contributing to the performance of the wind energy sector by aligning it with an operational circularity approach.”

DNV certified recyclable thermoplastic resin to enhance the development of the wind industry’s first recyclable wind turbine blade. For the resin types ELIUM® 188 O and XO, DNV had issued a Type Approval based on its Class Programme for thermoset resins, amended with additional requirements based on DNVs blade Standard DNV-ST-0376 to cope with the specifics for thermoplastic resins.

By the end of the project in 2023, the consortium will have met the challenge of bringing the wind energy sector into the circular economy loop in a sustainable manner, according to the principles of eco-design.